Choosing the right Webbing Sling is critical for ensuring lifting safety, load stability, and long-term operational efficiency in industrial environments. With various materials, load capacities, and configurations available, improper selection can lead to equipment failure, workplace accidents, and costly downtime. This in-depth guide explains how to choose the correct webbing sling based on load weight, lifting method, safety factors, and application scenarios, helping buyers and engineers make informed decisions.

Table of Contents

- What Is a Webbing Sling?

- Why Choosing the Right Webbing Sling Matters

- Types of Webbing Slings Explained

- Webbing Sling Materials and Their Properties

- How to Determine the Correct Load Capacity

- Step-by-Step Guide to Selecting a Webbing Sling

- Webbing Sling vs Other Lifting Slings

- Industrial Applications of Webbing Slings

- Inspection, Maintenance, and Service Life

- Frequently Asked Questions

What Is a Webbing Sling?

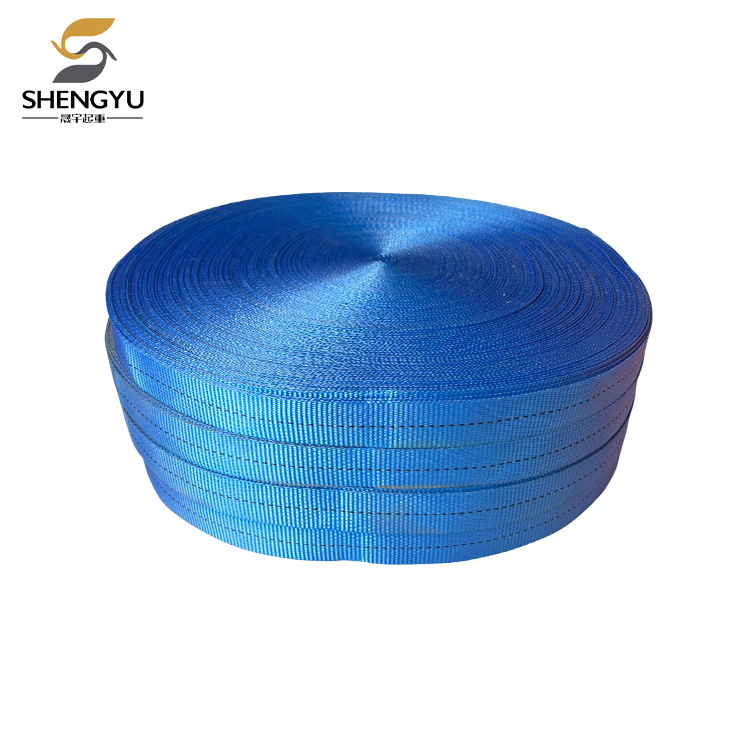

A Webbing Sling is a flexible lifting sling made from high-strength synthetic fibers, typically polyester, nylon, or polypropylene. Designed to lift, hoist, and secure loads, webbing slings are widely used in construction, manufacturing, logistics, marine operations, and energy sectors.

Unlike wire ropes or chain slings, webbing slings are lightweight, non-corrosive, and gentle on load surfaces. According to industry manufacturers such as webbing sling suppliers, these slings are especially suitable for lifting painted, polished, or fragile loads.

Why Choosing the Right Webbing Sling Matters

Selecting an incorrect webbing sling can result in load imbalance, excessive stress, premature wear, or catastrophic failure. In heavy lifting operations, even a small miscalculation can have serious safety and financial consequences.

- Prevent workplace injuries and accidents

- Ensure compliance with lifting safety standards

- Extend sling service life

- Reduce equipment downtime

- Protect valuable loads from damage

Types of Webbing Slings Explained

Understanding different webbing sling types is the first step toward proper selection. Each type serves a specific lifting purpose.

| Type | Description | Typical Use |

|---|---|---|

| Flat Webbing Sling | Single or multi-ply flat construction | General-purpose lifting |

| Endless Webbing Sling | Looped continuous design | Choker and basket hitches |

| Round Sling | Polyester core with protective sleeve | Heavy or irregular loads |

Webbing Sling Materials and Their Properties

Material selection directly affects strength, stretch, chemical resistance, and environmental performance.

| Material | Key Properties | Best Applications |

|---|---|---|

| Polyester | Low stretch, UV resistant | General industrial lifting |

| Nylon | High elasticity, shock absorption | Dynamic or shock loads |

| Polypropylene | Lightweight, moisture resistant | Marine environments |

How to Determine the Correct Load Capacity

Load capacity is the most critical factor when selecting a webbing sling. Always refer to the Working Load Limit (WLL), not the breaking strength.

- Determine total load weight

- Consider lifting configuration (vertical, choker, basket)

- Apply safety factors

- Account for environmental conditions

Step-by-Step Guide to Selecting a Webbing Sling

Professionals at Shengyu recommend following a structured selection process to ensure safety and efficiency.

- Identify load shape and surface sensitivity

- Select appropriate sling type

- Choose correct material

- Verify WLL and safety standards

- Inspect sling before use

Webbing Sling vs Other Lifting Slings

Compared to wire rope and chain slings, webbing slings offer unique advantages.

- Lighter weight and easier handling

- No surface damage to loads

- Corrosion resistance

- Improved operator safety

Industrial Applications of Webbing Slings

Webbing slings are widely used across industries including:

- Construction and infrastructure projects

- Manufacturing and assembly lines

- Shipping and logistics

- Energy and power generation

- Marine and offshore operations

Inspection, Maintenance, and Service Life

Regular inspection is essential to ensure webbing sling safety. Slings showing cuts, abrasion, chemical damage, or broken stitching should be removed from service immediately.

Frequently Asked Questions

How often should a webbing sling be inspected?

Webbing slings should be visually inspected before each use and undergo periodic formal inspections by qualified personnel.

Can a damaged webbing sling be repaired?

No. Once damaged, a webbing sling must be discarded to ensure safety.

Are webbing slings suitable for outdoor use?

Yes, especially polyester webbing slings, which offer good UV resistance.

Conclusion

Choosing the right Webbing Sling is not just a purchasing decision—it is a safety commitment. By understanding sling types, materials, load limits, and applications, lifting operations can achieve higher efficiency and reduced risk. Trusted manufacturers like Shengyu provide reliable webbing sling solutions designed to meet international standards.

If you are looking for expert guidance or customized lifting solutions, feel free to contact us today and let our team help you choose the safest and most efficient webbing sling for your application.